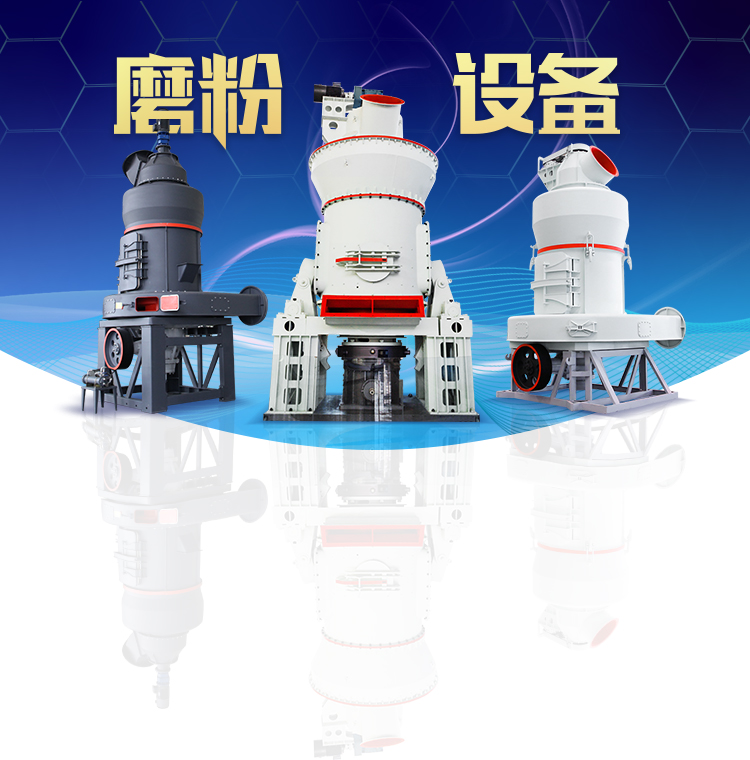

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

High Crushing Ratio Industrial Impact Crusher

.jpg)

Stationary HSI Impact Crushers, Horizontal

High reduction ratios and singlestage crushing for nonabrasive material in the aggregate industry allowing private quarry owners and recycling plants to recirculate oversize to primary, greatly reducing production capital outlayIt accepts larger feed sizes and features a higher reduction ratio compared to the jaw crusher These horizontal impact crushers are best suited for primary crushing applications where typical compression crushers (Eg jaw and cone) Our Range of Trio® Horizontal Shaft Impactor 2022年11月21日 They crush mediumhard to hard material mainly where a high crushing ratio and a cubical, stressfree end product are required, and they are used: for limestone, gypsum, Industrial Solutions Impact crushers ThyssenKruppEngineered for high production capacity and large reduction ratio crushing, the Trio® APS Series horizontal shaft impact crusher is renowned for its secondary crushing capabilities, without Trio® APS Series Horizontal Shaft Impact Crushers Weir

.jpg)

Nordberg® NP Series™ Horizontal shaft impact (HSI)

2023年7月20日 Nordberg® NP Series™ horizontal shaft impact (HSI) crushers are known for high reduction ratios when processing all type materials They deliver unbeatable performance Horizontal Shaft Impact (HSI) crusher primary range has been designed to increase the crushing process productivity thanks to its high reduction ratio Usually utilized in the first crushing stage Nordberg® NP1620™ impact crusher MetsoHAZEMAG’s HPI series of Primary Impact Crushers are used in the cement, aggregate and recycling industries For aggregate production, and in the recycling industry, HPI Impact Crushers are used for precrushing without a grinding pathPRIMARY IMPACT CRUSHER HPI HAZEMAGThe output size can be adjusted Features 1 Big crushing ratio, high crushing efficiency, cubic shape production 2 The gap between plate hammer and impact hammer can be adjusted, and the discharging size can be controlled Impact crusher PF1214 Henan LIMING Heavy

.jpg)

Trio® APP Series Primary Horizontal Shaft Impact Crushers

Engineered for high throughput and large reduction ratio crushing, the Trio® APP Series horizontal shaft impact crusher is renowned for its versatility under a wide range of operating 2022年9月29日 High reduction ratio for the Aggregates Recycling Industry Very high crushing degree of large rocks at high throughput rates Choice of hydraulicallyactuated impact aprons [Impact Crusher HPIH] hazemag2022年8月29日 speed or cascade ratio Coupled with lower wear costs, the result has seen the Kinglink KLSeries VSI fi nd applications not only in traditional quarry and mining plants, but also in a range of industrial mineral and specialist crushing operations The Kinglink KLSeries Vertical Shaft Impact (VSI) crusher has had a huge impact on theVertical Shaft Impact Crusher machinerylinefoThe impact crusher achieves very high crushing ratios in both the first and second stage This results in a wide range of salable, cubical final products The impact crusher can be repurposed into an impact mill for manufacturing fine grains by Impact crushers and mills with a horizontal shaft

.jpg)

Impact Crusher an overview ScienceDirect Topics

The impact crusher (typically PE series) is widely used and of high production efficiency and good safety performance The finished product is of cube shape and the tension force and crack is avoided Compared with hammer crusher, the impact crusher is able to fully utilize the highspeed impact energy of entire rotor2024年4月19日 The highspeed impact forces can wear down the crushing elements rapidly when processing very abrasive materials Attrition Crushing: Abrasion crushing is the consequence of material being subjected to the grinding action, often between two rotating surfaces or media This is the reason why there is a decrease in particle size due to abrasion Types of Crushers Explained: Everything You Need to KnowAPF Series APF series is the most common small impact crusher for sale Philippines It is a twocavity impact crusher that can crush hard rock Thus, the impact stone crusher is widely applicable for coarse and medium crushing stagesWith two counterattack chambers, the APF series secondary impact crusher for sale Philippines has features of large processing capacity, Impact Crusher For Sale Philippines 37~400tph Capacity2022年9月29日 Impact Crusher High reduction ratio for the Aggregates Recycling Industry Very high crushing degree of large rocks at high throughput rates Aggregate and recycling industry In the aggregate and recycling industry, the HAZEMAG Impact Crusher is used in the precrushing role without a grinding path Feed material up to 12 m3 Impact Crusher [Impact Crusher HPIH] hazemag

.jpg)

Our Range of Trio® Horizontal Shaft Impactor (HSI) Crushers

It accepts larger feed sizes and features a higher reduction ratio compared to the jaw crusher These horizontal impact crushers are best suited for primary crushing applications where typical compression crushers (Eg jaw and cone) have difficulty meeting strict particle shape requirements Compared to the Trio® APS Series, the Trio® APP It is suitable for handling brittle materials of medium hardness with side length not exceeding 500mm and compressive strength not exceeding 350 mpa The impact machine has the characteristic of large crushing ratio, low energy consumption, high efficiency of hard rock crushing, and a wide range of particle size adjustmentsImpact Crusher Impact Rock Crusher AGICO Cement Plant2023年7月20日 High capacity combined with high reduction ratio results in high performance crusher In addition, whenever tertiary crushing stage can be avoided, the capital costs and need for energy drop notably Durable wear parts and mechanical components reduce maintenance costs Mechanical reliability, simplifiedNordberg® NP Series™ Horizontal shaft impact (HSI) 2023年9月26日 High efficiency: The impact crusher has a large crushing ratio and high production efficiency Due to its unique crushing principle, the materials can be fully crushed during the crushing process, thereby improving production efficiency Simple structure: The impact crusher has a relatively simple structure, easy maintenance and easy operationWhat are the advantages and disadvantages of impact

Nordberg® NP Series™ impact crushers Metso

Nordberg® NP Series™ horizontal shaft impact (HSI) crushers are known for high reduction ratios, especially when processing soft and mediumhard materials High capacity combined with high reduction ratio results in high performance 2024年10月19日 PFW1315, PF1214, and PF1210 impact crushers perform well in processing mediumhard materials, with high crushing efficiency and large crushing ratio The product shape is mostly cubic, with the advantage of Impact Crushers Heavy Duty Aggregate NFLG tracked mobile impact crusher NFI1313 is equipped with the latest optimized and upgraded IH series impact crusher the perfect combination of heavy duty rotor, unique crushing caving and high wearresistant materials, making it show a large crushing ratio and high production capacity when crushing limestone, dolomite, coal mines and other mediumsoft hardness, mediumlow Tracked mobile impact crusher NFI1313 PT Fajar Mas MurniWith high reduction ratios, the HAZEMAG’s HPC Compound Crushers are used for Primary Crushing duties in the Cement Industry – producing feed material for further processing in a ball mill whatever the primary crushing application may be: stationary, semimobile, mobile HAZEMAG impact crushers can handle individual lumps of feed IMPACT CRUSHERS HAZEMAG

.jpg)

LF Large Diameter Impact Crusher With High Efficiency

LF Large Diameter Impact Crusher has the characteristics of a large crushing ratio, good product grain type and uniform grain size chemical industry, building materials, electric power, transportation and other industrial sectors Crushing materials: ore, limestone, slag, coke, etc Introduction This impact crusher for sale is a kind of The mobile crushing plant R900 guarantees highest performance at a very high crushing ratio Due to 2 hydraulically adjustable swingbeams, as well as variation of the rotor speed, the final grain can be optimally influenced Optional DUPLEXSystem: The hydrostatic drive system allows a clockwise or anticlockwise operation of the crusherHydraulic impact crusher R900 Rockster Austria 2023年2月23日 What is an Impact Crusher? Impact crushers, also known as impactors or horizontal shaft impact crushers, are crushing machines that use the principle of impact crushing to crush materialsThey are commonly used in mining, construction, and recycling industries to produce highquality cubical aggregates from various materials, including hard rock, soft rock, Understanding the Impact Crusher Working Principle for Efficient Crushing2024年8月14日 Check Out the Features of our Impact Crushers: Andreastype impact crusher design Produces highly cubical product High ratio of reduction Hammers have four crushing positions to maintain a more constant gradation and greater topsize controlImpact Rock Crushers: A Comprehensive Overview

High Crushing Ratio Sand Making Machine /Sand Making Fine Impact Crusher

2003年3月18日 High Crushing Ratio Sand Making Machine /Sand Making Fine Impact Crusher: PCX highly effective impact fine crusher (the third generation sand making machine) is a new type sand making equipment developed by combining the domestic and overseas technology with the working conditions of related industries2023年10月11日 Impact Crusher High reduction ratio for the Aggregates Recycling Industry Very high crushing degree of large rocks at high throughput rates Aggregate and recycling industry In the aggregate and recycling industry, the HAZEMAG Impact Crusher is used in the precrushing role without a grinding path Feed material up to 12 m3 Impact Crushers[Impact Crushers HPIH] HAZEMAG2023年11月10日 Impact crusher PF1315 is a crushing equipment that uses impact energy to crush materials It is a mediumsized stone crushing equipment with three crushing chambers and a large crushing ratio It can process a variety of sand Impact crusher PF1315 Aggregate Rock Crushing 2024年10月25日 Besides, the main advantages of impact crusher include large crushing ratio, good material shape after crushing, adjustable discharging particle size, and diversified crushing specifications (stone can be crushed and sand Impact Crushers for sale in Indonesia Factory

.jpg)

Crushing and Screening Handbook AusIMM

2021年6月24日 secondary, tertiary or quarternary crushing applications High performance technology Impact crushers – primary and secondary machines for soft and mediumhard materials High reduction ratios Can eliminate need for a tertiary crushing stage Spare and wear parts – genuine parts always close to you, no matter where you are located worldwideZEUS has a long experience in manufacturing of Horizontal shaft impact crusher for various crushing requirements These crushers are use in primary and secondary crushing requirements ZEUS Impact crusher known for their higher crushing ratio, low dust production and high performances Application Area: Aggregate; Coal and Power plant sectorImpact Crusher Manufacturer in India Zeus Engitech2022年9月29日 Impact Crusher Redefines secondary crushing technology High reduction ratio for the Cement, Recycling Aggregates Industry Reliable production at up to 700 t/h while utilising costefficient wear materials Ease of operation and a consistent product standard thanks to hydraulically –actuated impact aprons[Impact Crusher HSI] hazemag2024年2月20日 Discover the difference between impact crusher vs jaw crusher Learn how these two crushing machines vary and find the right one for your needs High reduction ratio, good for soft to mediumhard materials: Cone Crusher: Secondary/Tertiary: Gold, Copper, Silver: Up to 300mm (12 inches) 20mm50mm (0752 inches) High Crushing Capacity What's the Difference: Impact Crusher vs Jaw Crusher JXSC

.jpg)

R1000S Trackmounted impact crusher Rockster Austria

MAIN DIMENSIONS Feeding discharge height Width: 8‘5“ / 2,55 m Height: 10‘6“ / 3,20 m Weight: 68350 lbs / 31,0 t Main ~ 10‘6“ / 3,20 m discharge belt: Side ~ 7‘6“ / 2,30 m discharge belt: Transport dimensions TECHNICAL DETAILS MAXIMUM FLEXIBILITY The Rockster impact crusher guarantees highest performance at a very high crushing ratio2024年3月4日 Impact Crusher Applications: Aggregate Production:Impact crushers are extensively used in aggregate production for crushing materials like limestone, granite, and basalt Their high reduction ratios make them effective in producing wellgraded and cubical aggregates for construction projects Mining Operations:In mining applications, impact Impact crusher application and spare parts introductionImpact crusher is new product designed by our company after absorbing the advanced technology home and abroad This kind of crusher can crush many kinds of materials with max feed size less than 500mm and crushing strength less than 360 MP It has the features of high ratio of crushing, high efficiency of crushing, easy to maintenance, etcImpact Crusher Liming Heavy IndustryHAZEMAG Secondary Impact Crusher The HSI series has been designed for the economic processing of either soft and mediumhard or hard rocks High Reduction Ratio For the Cement, Recycling and Aggregates Industry Depending on the feed material, the crushing ratio, and the desired product grain size, feed material sizes of up to 450mm can Secondary Impact Crusher HSI HAZEMAG

The 9 Best Mobile Impact Crushers:

2024年6月3日 The Metso Lokotrack LT1213 is a versatile and efficient mobile impact crusher designed for crushing a wide range of materials It features a Nordberg NP1213 impact crusher with a large feed opening and high crushing Jaw box in a jaw crusher Impact Crushers Reduction ratio 10:1 Impact Crushers can be used for either primary or secondary crushing and work by creating a sudden impact force that shatters the material into smaller piecesReduction Ratios in Crushing Machinery Partner2023年10月8日 4 Impact crusher The impact crushers are ideal for the secondary and tertiary crushing of coal with high moisture content They are used behind the jaw crusher and rarely suffer from blockage or motor burnout The 6 Types of Coal Crusher: Which Is Best for 2020年8月18日 HSI crushers can achieve very high reduction ratios A HSI crusher works work by accelerating the rock as it is fed from the top, from where it’s caught by the upward facing rotor, If impact crushing is opening a walnut with a hammer, compression crushing is the nutcracker A steady compression force applied by closing the product between Understanding comminution: Compression versus impact crushing

.jpg)

Impact Crusher, Horizontal Shaft Impact Crusher GEP

5 天之前 Impact crushers use impact to reduce the size of the material and are suitable for handling a variety of low to medium hardness materials, usually used as primary or secondary crushing When the impact crusher is in operation, the motor drives the rotor to rotate at high speed and the material enters and falls onto the rotor, which strikes the 2022年8月1日 Impact Crusher Impact crusher, which has the advantages of simple structure, large crushing ratio, low energy consumption, high output, light weight, cubic shape of crushed products, is widely used in various ore crushing, railway, expressway, energy, cement, chemical industry, construction and other industries6 Stone Crushers In South Africa Save Time Money Zenith Crusher2024年10月24日 Industrial Crusher Crushers crush stone by compression or impact and are used in a wide range of applications in the quarrying and mining industries impact crushers, cone crushers, etc Thanks to their high crushing ratios and reliable performance, jaw crushers and impact crushers are more often used in aggregate production and Industrial Crusher, Crusher Machine for CD Waste, Stone 2021年11月18日 Shandong Bangde Heavy Industry Technology Co, Ltd is a largescale machinery manufacturing enterprise approved by the relevant state departments and encouraged to invest The predecessor of the enterprise has experienced 17 years of ups and Shandong Bangde Heavy Industry Technology Co, Ltdjaw

.jpg)

Industrial Solutions Impact crushers

2022年5月19日 Industrial Solutions Our solutions for the Fields of application and design characteristics They crush mediumhard to hard material mainly where a high crushing ratio and a cubical, stressfree end product are required, and they are used: for limestone, gypsum, slag, over Stationary singleshaft impact crusher fed by two apron KREAT MOBILE IMPACT CRUSHING PLANT Impact crusher of this plant is particularly designed with heavy duty super rotor, large crushing cavity, heavyduty impact plate, highly antiabrasion alloy plate hammer, and hydraulic lifting deviceYUNNAN KREAT HEAVY INDUSTRY SCIENCE

徐州恒业滑石粉设备雷蒙磨

--每小时产1800T立式磨方解石破

--硅石粉碎机械厂家

--打包机械技术支持:中企动力打包机械技术支持:中企动力打包机械技术支持:中企动力

--钢渣磨粉440目以上用什么设备?钢渣磨粉440目以上用什么设备?钢渣磨粉440目以上用什么设备?

--如何操作立磨

--预粉磨砂粉立磨精品砂粉设备滑石粉设备雷蒙磨

--湿打矿石磨粉机

--hJm800磨机

--方解石矿破磨厂家

--海量高清载带成型机图片大全

--方解石场小型方解石磨粉机

--生石灰纳米比亚矿石打粉机浙江萧山

--每天处理400方石头用多大的高细立磨

--四川矿机

--雷蒙磨标准应用手册下载

--云南旭峰钢铁

--进口矿山 磨机

--做拉粉机器多少一台

--方解石粉磨有限公司章程

--制粉机械1060雷蒙磨参数

--矿石磨粉机除尘设备公司

--商品混凝土生产流程图

--高铁工业磨粉机厂家

--中低温煤焦油生产针状焦

--料理机能将阿胶磨成粉吗

--徐州雷蒙磨粉机厂家,锂辉石搅拌站

--矿石磨粉机链环

--22米球磨机轴承磨中空

--菱镁矿粉碎粉磨系统

--