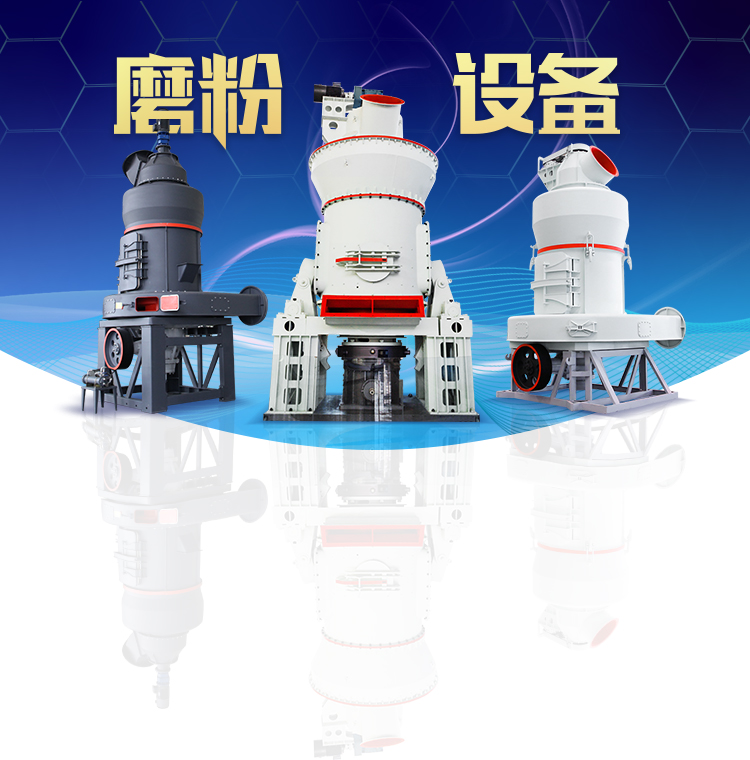

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Mill Versus Sheet Ball Mill

.jpg)

Navigating Ball Mill Specifications for Theory‐to‐Practice

2024年8月15日 Considering that for efficient milling results ball mill manufacturers recommend a filling factor of ~30 % in planetary ball mills, using lowdensity balls will thus exceed the reported filling factor, whereas highdensity balls may fall short of the target2019年1月11日 In this study, samples of bauxite whose chemical composition and Hardgrove Index values are known were ground to micronized size by a laboratory scale stirred media Performance comparison of stirred media mill and ball (BOND) mill 2017年6月2日 Ball mills use a tumbling process with stone or metal balls as the grinding materials to reduce the coarse material by means of impact and friction Ball mills typically use water or other liquid and additives to help reduce How it Works: Crushers, Grinding Mills and 2017年5月26日 Specific energy requirements for the proposed HPGR ball mill circuit and HPGR stirred mill circuit were determined from a pilotscale HPGR and stirred mill test, in COMPARISON OF HPGR BALL MILL AND HPGR

A comparative study on a newly designed ball mill and the

2020年1月1日 Mill with lifters has minimum recirculating load compared with mill without lifters The discharge end design of a ball mill plays an important role in discharging the desired 2021年3月12日 Ball mills and grinding tools Cement ball mills are typically twochamber mills (Figure 2), where the first chamber has larger media with lifting liners installed, providing the BALL MILLS Ball mill optimisation Holzinger Consulting2018年2月20日 Therefore, the regrinding circuit of Germano second concentrator offers an interesting opportunity: a vertical mill operating in parallel with two ball mills During almost two Comparing ball and vertical mills performance: An 2009年6月1日 Comparison of a laboratory vertical shaft stirred mill with a ball mill, both operated in a virtually closed circuit with a classifier, indicated that on average 30% energy saving can Comparison of energy efficiency between ball mills and stirred mills

A Comparative Analysis: Vertical Roller Mill vs Ball Mill

2023年9月21日 The main differences between a ball mill and a roller mill are in their grinding structure, design, efficiency and application areas Here are the key distinctions: Grinding 2024年8月15日 It becomes even more confusing when a different type of ball mill is used, such as a mixer mill versus a planetary mill Results obtained from mixer mills are reported in Hertz (Hz), whereas planetary mills in revolutions per minute (rpm) Therefore, each ball mill model will feature a different energy profile dependent on its planetary Navigating Ball Mill Specifications for Theory‐to‐Practice 2019年11月26日 The feed of the ball mill contains grinding balls In order to effectively reduce the direct impact of materials on the ball mill feed bushing and improve the service life of the ball mill feed bushing, the feeding point of the What’s the Difference Between SAG Mill and Ball 2024年8月8日 Ceramic Balls: Composed of materials like silicon nitride, alumina, and zirconia, ceramic balls are favored for their exceptional hardness and resistance to wear, corrosion, and high temperatures These properties Ball Mill Success: A StepbyStep Guide to

(PDF) Effects of Ball Size Distribution and Mill Speed and

2020年7月2日 In recent research done by AmanNejad and Barani [93] using DEM to investigate the effect of ball size distribution on ball milling, charging the mill speed with 40% small balls and 60% big balls 2015年11月23日 Relation of Bond ball mill work index and rod mill work index The Bond rod mill and ball mill work indices are the most similar in size classes, both being fed material crushed to “relatively fine” sizes Both test are also lockedcycle tumbling tests where the charge of ore in the mill is brought to a steady state over the duration of a pare and Understand Rod/Ball/ImpactCrushing/Abrasion 2016年6月6日 These mills typically grind ROM ore in a single stage A large example of such a mill was converted from a singlestage milling application to a semi autogenous ballmillcrushing circuit, and the application is well described This refers to highaspect AG/SAG mills Ball Charge Motion inside a SAG Mill With a higher density mill chargeSAG Mill Grinding Circuit Design 911Metallurgist2024年8月10日 In the rolling process, the job is drawn through a set of rolls due to interface friction, and the compressive forces reduce the thickness of the workpiece or change its crosssectional area The types of rolls used in rolling mills depend upon the shape, size, and gap between the rolls and their contour Because of workability and limitations in equipment, rolling Rolling Mills: 6 Different Types of Rolling Mills [Images PDF]

.jpg)

Energy Efficient Ball Mill Circuit – Equipment Sizing Considerations

2013年7月15日 The ball mill in closed circuit with hydrocyclones is an industry standard, and well known methodologies exist for equipment sizing, selection and design2021年1月12日 The hammer mill works by impact between rapidly moving hammers and powder materials, while the ball mill uses impact and attrition between rapidly moving balls inside a rotating cylinder Both provide descriptions of their basic principles, constructions, operating parameters, advantages and disadvantagesHammer mill and Ball mill PPT Free Download SlideShare2023年11月24日 End mills come in different shapes (square, ball nose, corner radius) and coatings to suit different machining needs What is the Difference Between a Face Mill and Fly Cutter What is a Drilling Services CNC Milling Services CNC Machining Services 5 Axis Machining Services swiss machining Services 3D Printing Sheet Metal Fabrication Face Mill vs Shell Mill vs End Mill Cutters: Differences2021年1月1日 Comchambered with the design of Φ 35 × 13m threechamber ball mill, the design process of ball mill is described in detail General arrangement of the mill Filling rate of grinding body in each (PDF) Design of Threechamber Ball Mill

.jpg)

Ball Mill vs SAG Mill: What’s the Difference? At

As a general rule, SAG mills tend to be more expensive to acquire and maintain than ball mills, however, the costbenefit analysis must consider the total cost of operation over the life of the mill To get a closer look into quotes and details, 2016年1月23日 The grinding process in ball mills and vertical roller mills differ fundamentally In a ball mill the comminution takes place by impact and attrition The comminution in the vertical roller mill takes place by exposing a bed of material to a pressure sufficiently high to cause fracture of the individual particles in the bed, although the Cement grinding Vertical roller mills versus ball mills2009年6月1日 At product sizes finer than 80% passing 75 μm, the efficiency of ball mill grinding rapidly decreasesThe practical limit to ball mill product fineness is considered to be 40–45 μm (Gao and Weller, 1994)Although ball mills can still be found in the regrind circuits in a number of mineral processing plants, their energy consumption is high, and size reduction efficiency is parison of energy efficiency between ball mills and stirred mills 2020年7月3日 This document outlines inspection procedures for the ball mill at Arish Cement Company's production department It details checking various parts of the mill like the inlet, feeders, liners, ball charge, and diaphragms Measurements are taken to monitor wear, ensure proper material flow, and maintain grinding efficiency The goal is to prevent issues that could Ball Mill Inspection Procedure PDF PDF Mill (Grinding)

.jpg)

BallMills Versus EndMills for Curved Surface Machining

The use of endmills for machining low curvature surfaces is examined in relation to the more popular ballmills Endmills are shown to give a better match to the required surface geometry and hence reduce the number of surface passes required They also have a much better efficiency of material removal and longer tool life It is shown that the use of endmills for 2022年6月24日 The ball mill is a horizontal cylindrical rotating device, and the material is fed into the first silo of the ball mill by the feeding device through the feeding hollow shaft There is a stepped liner or corrugated liner in this warehouse, which is How to choose between ball mill and vertical roller mill?2023年2月26日 The main difference between a lathe and mill is that a lathe handles primarily round pieces of material, while a mill shapes them into more complex designs Process of Turning on a Lathe The process of turning on a lathe is a type of machining process that creates objects with symmetrical, round, or tapered profiles by rotating the item held in Lathe vs Mill: What’s the Difference and Which is Better?2017年10月26日 a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that take this factor into account As well, mills with different length to diameter ratios for a given power rating will yield different material Factors Affecting Ball Mill Grinding Efficiency 911Metallurgist

.jpg)

Cement grinding Vertical roller mills versus ball mills

Cement production is one of the most energyintensive manufacturing industries, and the milling circuit of cement plants consumes around 4% of a year's global electrical energy production2024年10月11日 Ball mill is the most widely used kind of grinding equipment Zenith Ball mills are widely used in various types of ores' benefication, electricity, cement and chemical industries With high comminution ratio,it can carry out dry or wet pulverizing and can meet demand for sustainable largescale productionMQ Series Ball Mill Shanghai Zenith Company2021年3月12日 Ball mills and grinding tools Cement ball mills are typically twochamber mills (Figure 2), where the first chamber has larger media with lifting liners installed, providing the coarse grinding stage, whereas, in the second chamber, medium and fine grinding is carried out with smaller media and classifying linersBALL MILLS Ball mill optimisation Holzinger ConsultingIn summary, a ball mill and a planetary ball mill have similar basic designs but differ in terms of size, capacity, grinding mechanism, applications, and noise/vibration levels Planetary ball mills are more suitable for fine grinding and laboratory use, while traditional ball mills are commonly used in industrial settings with larger capacitiesWhat Is The Difference Between A Ball Mill And A Planetary Ball Mill

.jpg)

A Comparative Analysis: Vertical Roller Mill vs Ball Mill

2023年9月21日 The material is fed between the rollers and is crushed or ground as it passes through the gap between the rollers Roller mills are generally larger in size compared to ball mills Grinding Efficiency Ball Mill: Ball mill is known for their high grinding efficiency The grinding media (balls) have a larger surface area and impact the material Ball mill grinding machines are valuable tools in various industries, offering efficient and reliable grinding and mixing capabilities Understanding their working principle, different types, parts, applications, advantages, and recent developments helps to appreciate their significance and wideranging applications in industries such as cement Ball Mill Grinding Machines: Working Principle, Types, Parts 2016年10月12日 An increase in the diameter of a mill gives greater economy in two ways : In the first place, the balls do more effective work in a large than in a small mill, because, falling from a greater height, they shatter the pieces of ore with greater force ; in the second place, the ratio of the deadweight of the mill to the weight of the ball charge Closed Circuit Grinding VS Open Circuit Grinding2012年6月1日 S h i, F Comparison of Grinding Media – Cylpeb s Versus Balls – Minerals Engineering, Vol 17, 2004, 12591268 43 Ball mills can grind a wide range of materials, including metals (PDF) Grinding in Ball Mills: Modeling and Process Control

.jpg)

Closed circuit ball mill – Basics revisited ScienceDirect

2013年4月1日 The ball millhydrocyclone circuit and the ball millscreen circuit were sampled in order to measure and compare the performance of the circuits The ball mills are different in design Therefore, simulation studies were carried out to eliminate the differences in factors affecting the performance of the circuits such as milling conditions2015年9月1日 Discharge of pebbles, finer rock, ball scats and slurry from mills and its flow through trommels, and into other processing operations has strong impacts on overflow ball mill performanceSimulation of overflow ball mill discharge and trommel flow using Experimental verification results have shown that the tool orientation generated by the proposed method can obtain the expected machining strip width and roughness, meeting both macro and microscale requirements, so this method has significant potential for engineering applicationsBallMills Versus EndMills for Curved Surface Machining2024年1月10日 The Difference Between Ball Mill And Rod Mill Appearance and structure Although the appearance of ball mills and rod mills are very similar, the proportions of the two cylinder shapes are different The ratio of the barrel Ball Mill VS Rod Mill: Difference Selection

.jpg)

Fine Grinding as Enabling Technology – The IsaMill

3 天之前 These features distinguish stirred mills as fundamentally different from both ball mills and Tower Mills, as demonstrated by Tables 1 and 2 Table 1 : Typical Power Intensities of different Grinding Devices Table 1: Power Intensity of Different Grinding Devices Ball Mill is a 56m D x 64m L @ 26MW Tower Mill is a 25m D x 25m L @ 520KWBall mill A typical type of fine grinder is the ball mill A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the tumbling balls Ball mills normally operate with an approximate ball charge of 30%What is the difference between a SAG mill and ball mill?2017年6月2日 The feed enters one end of the ball mill, and discharges out the other end Ball mills vary greatly in size, from large industrial ball mills measuring more than 25 ft in diameter to small mills used for sample preparation in laboratories Rod mills are similar to ball mills and use metal rods as the grinding media Pebble mills use rock How it Works: Crushers, Grinding Mills and Pulverizers2023年11月28日 A flow sheet envisioned at the start of the work is shown in Fig The plant (ball mill) versus pilot plant (HPGr) comminution machine energy usages were compared using Work Index Efficiency and cumulative grinding rate analyses These accounted for differences between plant audit circuit feeds and the pilot plant test samples that were Replacement of Wet Ball Milling with HighPressure Grinding

.jpg)

Ball Mill vs Pebble Mill Neumann Machinery Company

2020年4月4日 The name “ball” or “pebble” refers to the type of grinding media that is introduced into the mill The media when combined with ores or other subtances accelerate particle size reduction by virtue of their impacting on the particles as the mill rotates The grinding action is as described in our article about how grinding mills work 2023年2月28日 The flat cutting head of a flat end mill is better suited for cutting straight lines and flat surfaces but is not as effective for machining complex shapes and contours as the ball nose end mill Ball nose end mills are best suited for machining curved surfaces and 3D shapes, while flat end mills are better suited for milling flat or shallow Ball Nose vs Flat End Mill Ball Nose End Mill Speeds and 2024年7月2日 Sag Mill is a kind of heavy duty equipment used in the ore crushing and grinding industry Its working principle is to utilize the impact and grinding effect of a small amount of steel balls and the material itself to crush the ore Through the rotation of the cylinder, large pieces of ore are gradually broken into smaller particles in the collision between the steel balls and the Choosing the Right Grinding Mill: SAG Mill vs Ball Mill JXSC2021年1月1日 As per European cement research academy's project “Future grinding technologies”, out of 1036 orders of grinding mills in 5 years, 58% were for Vertical Roller mill and 40% were for Ball Mill + HPGR circuit Hence Ball Mill VRM are major technologies in cement grinding Their technological comparison is done beneath [8]Review on vertical roller mill in cement industry its

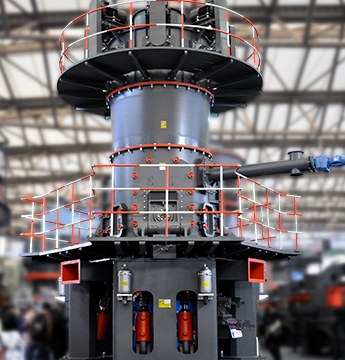

分设备自主创新出效益

--江西赣州市方解石粉磨设备生产现场

--矿石哪些地方有

--石英硅矿石的是多少

--立式矿石磨粉机产量950TH

--矿物磨粉机企业列表

--石灰石碳酸钙磨粉机型号规格

--SS磨白灰0矿石磨粉机技术

--1m1m的雷蒙磨多少钱

--石粉与石头高钙粉的区别

--生料粉矿山机器

--水泥立式磨机系统图

--选煤厂设计

--液压式岩石磨粉机HB40G

--6R雷蒙磨粉机产量60TH

--能磨碳酸锂的机器

--时产8001200吨花岗闪长岩高钙粉机

--津巴布韦方解石矿开采权公司迈入了一个全新的领域

--摆式磨粉机生产单位

--重钙微粉磨氧化钙研磨机纸

--磨煤机hmi

--焦煤石灰石制粉设备研磨机

--开产沙证

--高温炉渣强制水冷却蒸汽回收

--石灰特粉机

--石头粉体加工粉磨设备

--6S1245锑华碎石灰石粉碎机

--花岗岩碎

--石灰石粉粒得用途石灰石粉粒得用途石灰石粉粒得用途

--红岩中速磨粉机器

--