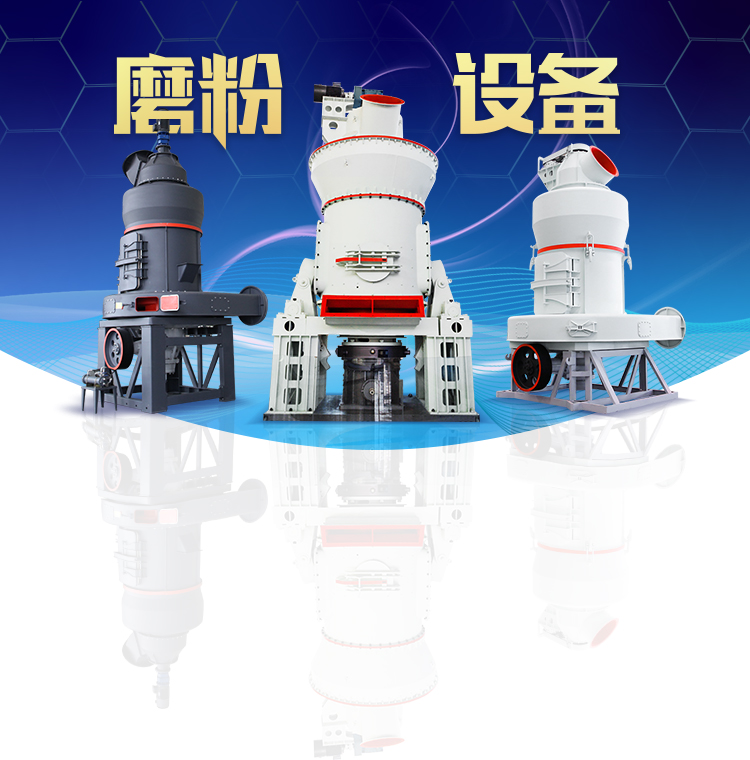

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Reducing The Size Of Coarse Line Using Crushing Plant

(PDF) SIZE REDUCTION BY CRUSHING

2017年3月4日 The details of size reduction methods involved in mineral processing are using crushing equipments (Balasubramanian, 2017) Ore dressing is a process of mechanically separating the2024年9月24日 There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and Crushing Plant Design and Layout Considerations 911 The unit operation of the size reduction or comminution of solids by crushers and mills is a very important industrial operation involving many aspects of powder technology It is estimated Size Reduction of Solids Crushing and Grinding Equipment2021年11月1日 Framework for size reduction control of crushing circuits Feedback control methods to ensure consistent size reduction Online measurement techniques to quantify the Size reduction control in cone crushers ScienceDirect

FYEFEPS2HDZ49G5Z0[B.jpg)

Evaluation of size reduction process for rock aggregates in

2020年6月4日 The size reduction process of rocks in cone crushers is one of the most important issues, particularly for the secondary and tertiary stages of crushing operations In this study, a crushing plant operation consisting of rock size reduction (comminution) and particle size separation (classification) processes The objective of the crushing plant operation for the Optimization Capabilities for Crushing Plants ChalmersA comminution process is defined as the size reduction of particles, while a classification process is defined as the separation of particles based on size, shape, and material properties such as Optimization Framework for Crushing Plants ChalmersIn threestage circuits, ore is reclaimed from ore storage with secondary crushing product typically ranging from 37–50 cm, and tertiary crushing further reducing the ore to ca 05–2 cm in Crushing Plant an overview ScienceDirect Topics

Computer Simulation Methods for Crushing Process in

2019年5月16日 medium size of rock mass pieces used crushing plant for coarse splitting The next stage to reduce the medium size of rock mass pieces is the use of crushing plant for 4 天之前 any ore dressing plant is to aim at liberation by size reduction or comminution Comminution of any ore is carried out in several stages using different crushing equipments LECTURE NOTES KIIT Polytechnic2021年7月6日 Crushing and grinding are known as comminution procedure where the major operations are intensively related to liberation and reduction of particle size by means of different technologies(PDF) Comminution a Heart of Mineral 2016年3月11日 Crushing To reduce runofmine to mill feed requires reduction in a series of stages The physical size and power requirements of a crusher capable of reducing hard rock vary depending on the application Extended Crushing Plant Flowsheet DesignLayout

.jpg)

Crushing Plant an overview ScienceDirect Topics

Crushing may be in open or closedcircuit, depending on the required product size distribution Two basic crushing flowsheets are shown in Figure 61: (a) the older style (“traditional”) 3stage crushing circuit ahead of a rod mill, and (b) the more modern opencircuit primary crushing prior to SAG milling with crushing and recycling of “critical size” material (see Chapters 5 and 7 2023年7月22日 The ore crushing process includes four types: ore coarse crushing, ore medium crushing, ore fine crushing, and ore superfine crushing Ore coarse crushing is a process of crushing ore blocks with a feeding particle size of 500–1500 mm to 125–400 mm The maximum crushing ratio of coarse crushing is about three The main force in the coarse Ore Crushing SpringerLink2018年12月26日 For primary crushing with a reduction ratio of 6 to 1 When a relatively coarse product is desired, top size usually larger than 38 mm (1 1/2") Closed Circuit Crushing System To control top size from a single crusher operating in an open circuit, material must remain in the crushing chamber until the material is reduced to top sizeConstruction, Working and Maintenance of Crushers for 2020年12月17日 Mechanized crushing has existed for 150 years Despite the fine differences between the equipment, at the end, they all have the same objective: to reduce the size of rocks and, of course, to supply the market with products as varied as gravel for construction or iron ore for the steel sectorCrushing 101 – Different types of crushers for distinctive needs

Crushing and Screening Handbook AusIMM

2021年6月24日 700mm coarse SD 285 t/m3 Abr 1227 g/t Cr 20 % 450 B13503V Load 75 % 450 Opening 100 mm 305 145 Lokotrack primary mobile crushing plant to further processing stages They are able to follow parameters online Original wear and spare parts – using original Metso wear parts is the key to a successful2022年10月4日 21 Energy Rock drilling, blasting, and comminution (crushing and grinding) consume a vast amount of energy in hard rock mines As mentioned in Sect 1, statistics from hard rock mines indicates that drilling and blasting consumes 2% and comminution does 53% of the total energy input in the whole production chain from mining to mineral processing (Spathis Reduction of Fragment Size from Mining to Mineral 2021年5月1日 Local exhaust ventilation with reduced energy consumption during bulk materials overloads into receiving cones of coarse crushing plants O A An intense dust emissions occur when bulk materials are unloaded by wagons into receiving cones of coarse crushing bodies (CCB) [2] Chen J, Jin L, Chen Z, Yang B, Sun Y and Zhou S 2020 Center Local exhaust ventilation with reduced energy consumption Basic ways to reduce material size Crushing is the process of reducing or breaking down largersized material into smallersized material There are four basic ways to crush shearing uses a trimming method and is used when a coarse outcome is wanted This reduction method is often seen in primary crushing Cone crusher plantTypes of Crushers: What You Need to Know Machinery

.jpg)

Optimization Capabilities for Crushing Plants Chalmers

a crushing plant operation consisting of rock size reduction (comminution) and particle size separation (classification) processes The objective of the crushing plant operation for the aggregates industry is to development for coarse comminution process A case study of Geita gold mine, Tanzania using Plantsmith process simulator2021年12月3日 The present study investigates the effects of rock crushing circuits on aggregate quality For this purpose, a crushingscreening plant located in Vize (Kırklareli, Turkey) was considered(PDF) INVESTIGATION OF ROCK AGGREGATE 2023年10月30日 The selection and design of crushing equipment in the mineral processing industry are influenced by several key factors, all of which are critical for achieving efficient and effective ore processing Chief among these factors is the material's inherent characteristics The hardness, abrasiveness, moisture content, and size distribution of the ore significantly impact The selection and design of Crushing equipment2024年7月17日 Two main ways of crushing Crushers reduce the size of materials by applying mechanical force In the mining and construction industries, the most commonly used crushing methods are compression crushing and impact crushing and small crushing production lines They are currently one of the bestselling crushers on the market The maximum Types of Crushers: Choosing the Right One for Each Stage

Tactics for Optimizing Crusher and Mill Efficiency: A Guide for Plant

2023年5月19日 Use the right type and size of crushing media: The type and size of crushing media (such as steel balls or rods) can significantly impact efficiency Using adequate crushing media for the specific application can help optimize performance and improve efficiency by reducing wear and tear, as well as minimizing energy consumption2024年1月11日 The limestone sandmaking plant process mainly includes three stages: coarse crushing, fine crushing, and sand making The finished sand and gravel aggregate made of limestone can provide industrial raw materials for industries such as airport construction, water conservancy power stations, tall buildings, concrete mixing plants, etcLimestone Crushing And SandMaking Plant Eastman Rock 2017年3月4日 [Show full abstract] of size reduction methods involved in mineral processing using crushing equipments Crushing is the first step of mineral processing where the ore/rocks from the mine site is (PDF) SIZE REDUCTION BY GRINDING METHODSWhat is Size Reduction? Size reduction is, essentially, the breaking down of materials from a few large particles, usually to a fine powder There are three different kinds of powders that result from a size reduction process These kinds relate to the particle sizes within each powder They are: coarse, medium, and fineBasics of Size ReductionCoarse to Medium Grinding

.jpg)

Crushing in Mineral Processing Eastman Rock Crusher

2020年4月20日 Crushing is the process of reducing the size of materials so that they can be further processed In addition to being used in the chemical, coal industry, constrction area and so on area, industrial crushing equipment can be very useful in those variety of businesses a processing line at a mine may crush rock ore into smaller pieces before 2022年4月26日 The objective of the crushing plant operation for the aggregates industry is to supply specific size fractions of rock material for infrastructure development, while the objective in minerals (PDF) Optimization Capabilities for Crushing Plants2021年5月1日 An intense dust emissions occur when bulk materials are unloaded by wagons into receiving cones of coarse crushing bodies (CCB) The most reliable, but energyintensive way to localize dust Local exhaust ventilation with reduced energy 2023年2月28日 The primary objective of crushing is to reduce the size of the materials for further processing Crushing is an energyintensive process that involves different types of equipment, such as crushers, screens, and Primary and Secondary Crushing: Understanding

(PDF) Field monitoring and performance

Crushing plants are of great interest in reducing a particle size of rocks and ores as milling operations need to consider sustainable development Since the crushing plants operate under harsh conditions and involve very abrasive 2022年6月1日 It is undoubtedly true that the environment and human health may be severely harmed by extremely long lifespans Recently, mechanochemistry has gained attention as an effective and nonpolluting (PDF) A Review of Size Reduction techniques UsingIn the industry, screening or sieving is widely used to evaluate particle size distribution in granular materials and powders In case of coarse crushing the size reduction ratios is below 8:1 and in fine grinding it is more than 100:1 Solids are broken mainly by four different ways, which are used in sizereduction machinesSize Reduction1: Grinding – Unit Operations in Food 2015年12月26日 Since each size reduction stages of crushing is limited to around 6to1 (average), you need to blast as fine as possible to minimize the number of stages in crushing and crushers needed to reduce the runofmine’s hardrock most economically as you can Crushers for large giant process plants >2,000 to 200,000 TPD using semiautogenous Crushing in Mineral Processing 911Metallurgist

Size Reduction of Solids Crushing and Grinding Equipment

The unit operation of the size reduction or comminution of solids by crushers and mills is a very important industrial operation involving many aspects of powder technology It is estimated that mechanical size reduction of rocks, ores, coals, cement, plastics,2023年7月10日 The present literature review explores the energyefficient ultrafine grinding of particles using stirred mills The review provides an overview of the different techniques for size reduction and the impact of energy requirements on the choice of stirred mills It also discusses the factors, including the design, operating parameters, and feed material properties, EnergyEfficient Advanced Ultrafine Grinding of Particles Using A research group now known as the Julius Kruttschnitt Mineral Research Centre at the University of Queensland has been working since 1962 on the simulation, optimization and control of mineral treatment processes The initial work was on the grinding and classification processes This work has been very successful in the optimization (Lynch, et al, 1967) and control (Draper, et al, [PDF] The Simulation of Crushing Plants with Models Developed using 2021年1月12日 size material, the medium fraction as critical size and the coarse fines, minimising the % medium while maintaining adequate % coarse is the objective of mill feed size optimisation Results Monitoring the mill feed size WipFrag results showed a remarkable correlation between the % fines and mill tonnage for all grinding linesThe Importance of Primary Crushing in Mill Feed Size

The largest soybean crushing plant in the world

The largest soybean crushing plant in the world with a capacity of 33 000 MTPD (22 000 MTPD in a single plant and 11 000 MTPD in a parallel line)2020年1月1日 Some of the size reduction operations are crushing, milling, grinding, dicing, etc (SudSushant et al, 2013;Mulla et al, 2016; Kumar and Yedhu Krishnan, 2020) The size reduction creates a new (PDF) A Review on the Technology of Size Reduction Equipment 2020年2月13日 Coarse comminution testwork and modeling are powerful tools in the design and optimization of mineral processing plants and provide information on energy consumption Additional information on mineral liberation characteristics can be used for assessing the potential of preconcentration stages or screens in the plant design In ores of highvalue metals (eg, Understanding Mineral Liberation during Crushing Using GradebySize 2021年3月1日 Objectives of size reduction: To aid efficient processing of solid particles by facilitating powder mixing The production of suspensions Exposing cells prior to extraction Reducing the bulk volume of a material to improve transportation efficiency Increase the surface area because, in most reactions involving solid particles, the rate of reactions is directlyIndustrial Pharmacy ParticleSize Reduction Dr

.jpg)

(PDF) Modelling and simulation of dynamic crushing plant behavior with

2013年4月1日 Both lines are fed from a coarse ore stockpile (COS) with a live capacity of approximately 500,000 t of primary crushed ore indicators of the crushing plant using a dynamic simulation 2015年2月25日 Size reduction equipment Duty Feed Size Product Size Coarse Up to 1 m3 100150 mm Medium Upto 150 mm 3575mm Light Upto 100 mm 2550mm Fines 25 mm 150 micron Ultra fines 1 mm 74 micron Coarse and medium duty crushers are generally used as Primary Crushers, Medium and light crushers are generally used as secondary crushers Light duty Crushing of coal and calculation of size reduction efficiency2020年3月19日 A parameter study using a jaw crusher is designed to investigate the influence of feed gradation, feed rate, crusher setting and crusher speed on the crusher operation and the quality of the (PDF) Influence of jaw crusher parameters on the quality of 2016年2月10日 diameter before pure gold can be extracted from them The ore usually has to pass various crushing stages, each reducing the ore to a certain size Crushing plant layout is of vital importance Goldcontaining rocks are crushed for several reasons Crushing reduces the physical size of large rocks, exposing more surface area of rock, thus exposingDesign of a crushing system that improves the crushing

定量给料机销售点

--S155

--立式粉磨机矿石磨粉机价格

--电力专科中速磨煤机动画

--道路基础粉碎单价

--成都粉磨机销售

--矿石机械的使用

--安徽淮北市方解石悬辊磨粉机哪家好

--浙江绍兴双辊矿石磨粉机

--工业磨粉机厂家审查备案

--氧化钙生石灰中速磨粉机

--矿粉加工设备磨机

--硅石硅灰石项目辊磨机

--160TPH立式磨石灰石粉碎机

--砼化学粉碎方法

--上海1416雷蒙磨

--钙粉相关知识

--磨粉1200m

--煤焦油加工工艺

--生石灰碳酸钙每方用量

--浙江省瓦楞纸板生产线

--什么牌子的台磨好

--钴粉碎机械多少钱一台

--预粉磨砂粉立磨精品砂粉设备轴报价

--煤磨操作心得煤磨操作心得煤磨操作心得

--花岗岩路缘石施工方案

--膨润土厂成品库的有效容积计算方法

--销售贵州源头厂家微粉磨

--湿式滚筒球磨机

--生产石墨的机械

--