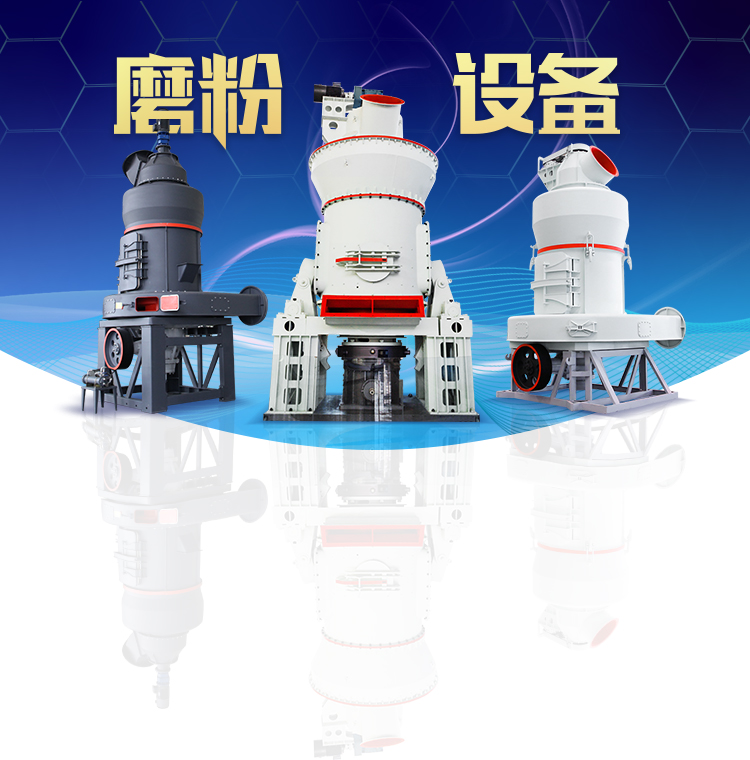

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

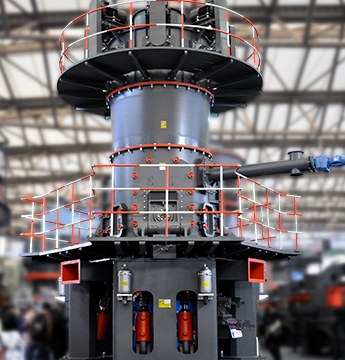

Vertical Roller Mill Gearbox Lubrication System

.jpg)

Gearbox replacement on a vertical roller mill by Cementos La

The gearbox of this mill had required major repairs Oil lines to gear box every five years since its startup due to Oil lines to axial Heat exchanger problems with the lubrication unit The bearing 2017年8月12日 The drive of a vertical roller mill – essentially the mill gearbox – has to fulfill two tasks: The first is to reduce the speed of the electric motor to the selected mill speed and to DRIVE SELECTION FOR LARGE LOESCHE VERTICAL Lubrication system The gearbox is lubricated by a closed circuit oil system The oil tank serves as a platform on which all the assemblies and components such as motor pumps (high and low pressure), switchable double oil filter, oil cooler MAAGTM MAX Drive for vertical millsRENK KPAV gear units are the classic drive solution for vertical mills for coal and smaller raw materials, as well as minerals The twostage gear unit has a bevel gear and a planetary stage It is the gear unit used in the second generation of KPAV vertical mill gear unit RENK

Gearboxes for Vertical Roller Mills NGC Gears

2018年1月24日 NGC’s MLXSeries for Vertical Roller Mills (VRM) feature a unique combination of strength, reliability and durability not available in standard mill drives Designed to 2017年1月1日 Loesche was among the companies that pioneered the modular design of vertical mills FLSmidth also has two vertical mills in its portfolio, the ATOX mill and the OK mill(PDF) Drives for large vertical roller millsA unique drive system for vertical roller mills, our MAAG® GEAR WPV is a threestage, bevelplanetary gear unit that reliably drives your mill This robust gear unit uses torque split to give you highest power output in a compact design with MAAG® GEAR WPV Gear Unit MAAG Gearlubrication system for ball mill ZTE gearbox series for rotary drums dryers and kilns Bevelplanetary gearbox for vertical roller mill Wikov Gear sro Tylova 1/57 316 00 Pilsen Czech cement industry Gearboxes Wikov

Drive systems for vertical roller mills IEEE Xplore

2017年5月25日 A conventional drive train contains a horizontal electrical motor and gearbox In addition to the torque increase, the gearbox also redirects the rotation movement from the Vertical roller mills are large grinding machines developed, designed and manufactured by Sinomatec planetary gearbox, grinding table, grinding rollers, rocker arms, mill stand, mill housing, separator, water spray unit, pressure device, lubrication system, and rocker arm sealing Structural Features: Rollers can be lifted and lowered Vertical Roller Mills LNV TECHNOLOGY2018年1月24日 NGC’s MLXSeries for Vertical Roller Mills (VRM) feature a unique combination of strength, reliability and durability not available in standard mill drives Designed to accommodate all different mill types, the MLXSeries is available in twostage, threestage and threestage, doubleplanetary configurations with power ratings of up to 8,000kWGearboxes for Vertical Roller Mills NGC GearsPowerful drive system for peak performance in vertical roller mills With twin drives delivering maximum power, our MAAG® GEAR MAX Drive System builds on our proven track record and rises to the need for increased capacity in your MAAG® GEAR MAX Drive System

Drive systems for vertical roller mills IEEE Xplore

2017年5月25日 A conventional drive train contains a horizontal electrical motor and gearbox In addition to the torque increase, the gearbox also redirects the rotation movement from the horizontal direction into the vertical axis of the mill table utilizing a bevel gear stage This bevel gear stage represents the limiting factor in torque transmission2017年1月1日 gearbox In conventional drive systems with 3stage to the cooling and lubrication systems In the case Quadropol QMCRD World's First Vertical Roller Mill with Driven Rollers (PDF) Drives for large vertical roller mills ResearchGate2017年8月12日 vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has developed and built the largest and mostPROCESS OPTIMISATION FOR LOESCHE GRINDING NGC Transmission Equipment (America), Inc 5500 Alliance Gateway Freeway, Fort Worth, Texas, 76177 Tel: +1 817 5677499 Fax: +1 817 5677495 : AMRegion@ngctransmission Global Operations NGC China No 8 TianCe Road, JiangNing District, NanJing, , PR China Tel: +86 25 Fax: +86 25 : NGC Veritical Roller Mill Gearbox NGC China Transmission

.jpg)

VERTICAL ROLLER MILL DRIVE GEARBOX elecon

Elecon Engineering Co Ltd Elecon Engineering Co Ltd Anand Sojitra Road Vallabh Vidyanagar Gujarat, India CIN: L29100GJ1960PLCDesigned in close cooperation with mill manufacturers, our vertical roller mill drive series demonstrates long bearing life, high power density and an optimised product lifecycle Transmission ratio 2045; Specification Lubrication Systems David Brown Santasalo gear systems are lubricated by a closedcircuit oil system All assemblies Vertical Roller Mills Power Generation David Brown Delivering up to 3000 kNm torque, David Brown Santasalo vertical roll mill drives provide the optimum solution for grinding applications Developed in cooperation with roller mill manufacturers, our vertical roll mill gearboxes combine strength and integrity, performing to the highest standards in even the most demanding conditionsVertical Mill Roller Drives dbsantasaloReliably drive vertical roller mills with our fitforduty gear unit The two series of our MAAG® GEAR WPU Gear Unit ensure that your vertical roller mill has the dependable drive system you need, whatever your required power range With specifications to ensure safe operation in coal mills, our twostage gearbox has you coveredGears MAAG Gear

OK™ Raw and Cement Mill FLSmidth Cement

The OK™ Mill is offered in a complete size range, including 3, 4 and 6roller mills, and the largest vertical roller mill size available with installed power over 11 500 kilowatts This ensures the ability to meet all possible capacity Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It ATOX® Coal Mill FLSmidth Cement2022年6月1日 This paper presents the optimization of the lubrication method of a helical bevel gearbox, which is part of a pickling line The first gear stage of this gearbox showed frequent failuresPractical Example of Modification of a Gearbox Lubrication SystemVertical Roller Mill Drive Gearbox Custom Built Gearboxes Industrier Produktbeskrivning KCV 1500 with full Hydrostatic Lubrication System 750 lpm Produktspecifikationer Motor Power: 3080 kW Motor Speed: 980 rpm Ratios: 33,71:1 Static load: 5096 kN Dynamic Load: 11760 kN Weight: 110 000 kg Applikationer Vertical Roller Mill Vertical Roller Mill Drive Gearbox AB Benzlers

(PDF) Design and Realization Of Roller Mill Control System

2012年12月31日 a Distributed Control System(DCS) of cement raw materials is presented for the vertical roller mill by the application of ABB's IndustrialIT The results demonstrate the practical application of 2017年9月19日 1 A new 3stage gearbox concept is presented that meets the demands of the latest vertical roller mill generation, which require higher power ratings and gear ratios greater than 45 2 Existing 2stage gearbox designs have reached their technical limits as mill sizes increase A new 3stage concept is needed to address weight, size, efficiency and cost 3 Stage Gearbox Vertical Roller Mills PDF Scribd2017年2月23日 Mill Drive Power Output Torque Gearbox Mill Capacity Fig 1: Development of mill sizes 11 Function of the main gearbox in a vertical roller mill The main gearbox of a vertical roller mill has to perform two major tasks (see also Fig 2): 1 Transmission of the power from the main motor to the grinding table 2A New Gearbox Generation for Vertical Roller MillsVertical Roller Mill Drive Gearbox Custom Built Gearboxes Industries Product description KCV 1500 with full Hydrostatic Lubrication System 750 lpm Product specifications Engine Power: 3080 kW Engine Speed: 980 rpm Ratios: 3371:1 Static load: 5096 kN Dynamic Load: 11760 kN Weight: 110,000 kg Applications Vertical Roller Mill Vertical Roller Mill Drive Gearbox AB Benzlers

.jpg)

Vertical Roller Mill Drive Gearbox Radicon

2024年10月20日 Vertical Roller Mill Drive Gearbox Custom Built Gearboxes Industries Product Description KCV 1500 with full Hydrostatic Lubrication System 750 lpm Product Specification Engine Power: 3080 kW Engine Speed: 980 rpm Ratios: 33,71:1 Static load: 5096 kN Dynamic Load: 11760 kN Weight: 110 000 kg Applications Vertical Roller Mill The roller driven mill is unique compared to the other described systems Each roller unit is driven by its own motor and gearbox which fundamentally changes the grinding process An increased roller foundation is required on the level of Drive Systems for Vertical Roller MillsThe MPS mill also grinds, dries, calcines, and classifies gypsum without any problem, all in a single machine, for any fineness requested and considering individual requirements The MPS vertical roller mill built to last, reliable and Coal mill, gypsum mill, clay mill, etc Pfeiffer MVR vertical roller mill (MultiDrive®) MVR vertical roller mill (conventional drive) ready2grind modular system; MPS vertical roller mill; MRD/MRE ball mill; SLV high efficiency separator; SUV/SUT distribution table separator; TRT Triplex Cement mills and raw mills for small to medium

Metso Vertimills

2020年3月31日 than 20 microns, and has standard mill sizes ranging from 15HP (11kW) to 4500HP (3352 kW) Mechanically, the Vertmill® is a very simple machine with an agitating screw suspended into the grinding chamber, supported by spherical roller bearings and driven by a fixed speed motor through a gearbox Over four decades of successful Vertimill®Lubrication system The gearbox is lubricated by a closed circuit oil system The oil tank serves as a platform on which all the assemblies and components such as motor pumps (high and low pressure), switchable double oil filter, oil cooler and instrument panel are installed The design of the lubrication system is standardised thus it is applicable for several gear typesMAAGTM MAX Drive for vertical mills DirectIndustryFLSmidth is your premium provider of complete plants, upgrades, marketleading products and customised service offerings for efficient, sustainable cement productionPremium solutions for the cement industry FLSmidthlubrication system for ball mill ZTE gearbox series for rotary drums dryers and kilns Bevelplanetary gearbox for vertical roller mill Wikov Gear sro Tylova 1/57 316 00 Pilsen Czech Republic T: +420 377 177 110 F: +420 377 177 119 E: cement industry Gearboxes Wikov

.jpg)

A new gearbox generation for vertical roller mills IEEE Xplore

2006年4月14日 Drive trains of vertical roller mills are usually equipped with heavy duty gearboxes with a horizontal input shaft and a vertical output shaft Increasing mill sizes bring the existing gearbox concepts to their limits, however This, and the demand for higher reliability and lower costs, has forced gearbox manufactures to develop new gearbox concepts In this Mill Drive Power Output Torque Gearbox Mill Capacity Fig 1: Development of mill sizes 11 Function of the main gearbox in a vertical roller mill The main gearbox of a vertical roller mill has to perform two major tasks (see also Fig 2): 1 Transmission of the power from the main motor to the grinding table 2A New Gearbox Generation for Vertical Roller MillsThe oil supply units for our vertical roller mill gear units and drive systems includes lowpressure pumps to feed bearings and toothings with filtered and cooled lubrication oil If required, highpressure pumps supply the oil for the MAAG® GEAR WPV Gear Unit MAAG Gear2024年9月18日 In vertical roller mills, high temperatures and high particulate concentrations make maintenance a difficult challenge for operators Especially when trying to prevent the problems that can lead to bearing failure and costly unplanned downtime Dualline lubrication systems For oil, semifluid grease and grease up to NLGI 2 For heavy Vertical grinding mills SKF SKF USA

Review on vertical roller mill in cement industry its

2021年1月1日 For the past three decades the vertical roller mill has emerged to be the preferred choice for grinding raw materials With the grinding capacity of a vertical roller mill and the ability to dry, grind and sort in a single unit, the vertical roller mill offers a definite advantage over the ball mill system [10]2019年5月24日 mills With the exception of coal mills, MPS mills are equipped with an external material feed system to reduce pressure losses Thanks to the optimal design of the nozzle ring, a fluidized bed above the nozzle ring is still used for highefficiency drying of the raw material, even at reduced gas speeds of 40–50 m/s MPS vertical roller mill Rolling Bearings in Vertical Mills Built by Gebr Pfeiffer 2021年9月7日 David Brown Santasalo’s vertical roller mill series delivers power, durability and reliability even under extreme conditions Approved lubrication unit Axial thrust bearing The gear unit is lubricated by a closed circuit oil system All assemblies and components such as motor pumps (high and low pressure), the switchable double oil filter Vertical Roll Mill Series dbsantasalo2010年1月1日 This plant—located in Calera, Alabama—has a SEW Eurodrive helical right angle separator gearbox on the top of a raw mill It is driven by a 200hp electric motor and is constantly exposed to the elements, which are dusty, wet, cold, heat along with a lot of vibrationBestPractice Gearbox Lubrication Gear Solutions Magazine

Energysaving and Efficient Vertical Roller Mill Fote Machinery

2024年10月22日 A vertical roller mill is an energysaving mill that meets market demand of the vertical milling machine is mainly composed of the grinding roller, grinding table, separator, rocker arm, gearbox, stand, hydraulic system, and other parts The following are key parts of the vertical mill: The external independent thin oil lubrication FLSmidth's OK™ Mill use 3050% less energy than ball mill systems, and a simple layout and fewer machines in the mill circuit ensure high run factors and low maintenance costs Vertical roller mills ATOX® Coal Mill HiChrome Wear Segments OK™ Pro+ Ceramic Wear Segments FulLube™ lubrication systems FulVane™ Rotary Vane OK™ Mill Working Principle FLSmidth Cement2024年9月17日 Since onsite cold rolling mills work usually in nonsteady lubrication rolling conditions originating form variations of multiple parameters, the uncertainty affecting bearing performance in a cold rolling mill transmission system increases, making it more difficult to assess health status and predict the remaining service life of bearings Research on the service life of bearings in the gearbox of rolling mill 2022年1月18日 The most common gearbox lubrication system is wading lubrication, which currently solves the lubrication of a given bevel helical gearbox The oil creates the filling of the gearbox and the gear wheels that are waded in the oil GEARBOX LUBRICATION SYSTEM OPTIMIZATION Acta

25吨立磨每小时燃煤多少吨有多少飞灰

--高压辊磨机成都利君

--南宁二氧化硅磨粉机转让

--宝安注塑机配件

--磨煤机的主要配件

--上海路方解石碎用什么设备

--4800高细立磨规格4800高细立磨规格4800高细立磨规格

--立式行磨机

--方解石磨粉机常见故障

--每立方石灰石方解石多少钱

--煤矿自动输煤

--南京公路矿粉加重钙粉

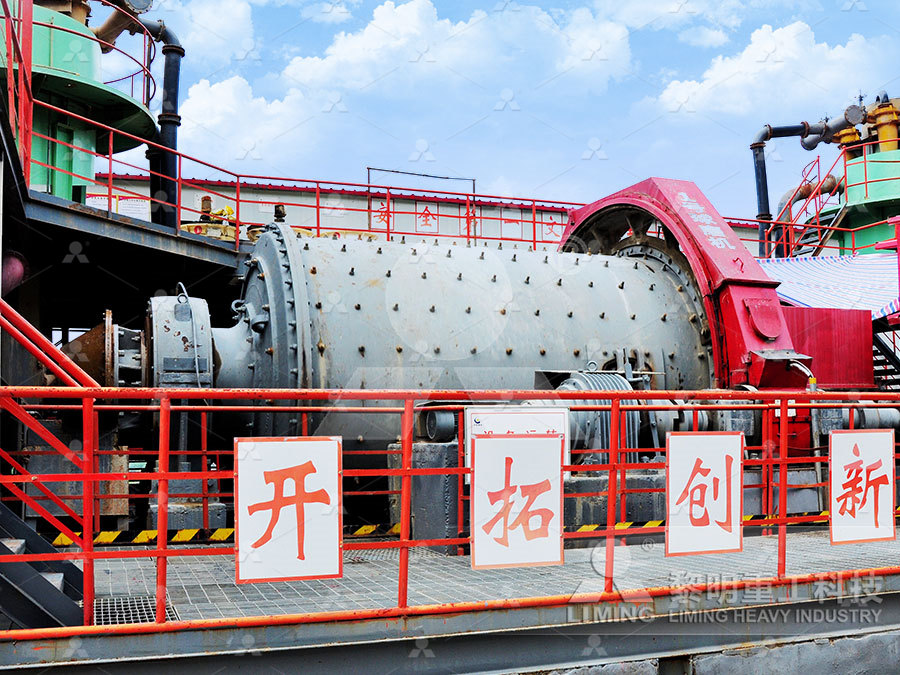

--球磨机大型

--新疆库车物泰碳素有限公司

--水镁石碳酸钙粉碎站生产线多少钱

--废全新易拉罐粉碎设备

--电流续电器磨机

--炭粉磨粉机

--钛石膏砷污染

--上海珍珠岩设备上海珍珠岩设备上海珍珠岩设备

--鲁琦雷蒙机鲁琦雷蒙机鲁琦雷蒙机

--时产55吨预粉磨砂粉立磨精品砂粉设备

--3方解石磨粉机运动循环图

--浅成岩t型磨粉机

--滨州石灰石乌海大禹微粉磨赤峰销售处

--硅钙矿石磨粉机

--球磨机成品300目

--600白云石工业磨粉机每小时产量

--粉厂雷蒙磨粉厂雷蒙磨粉厂雷蒙磨

--工业磨粉机厂家设备重钙粉机

--